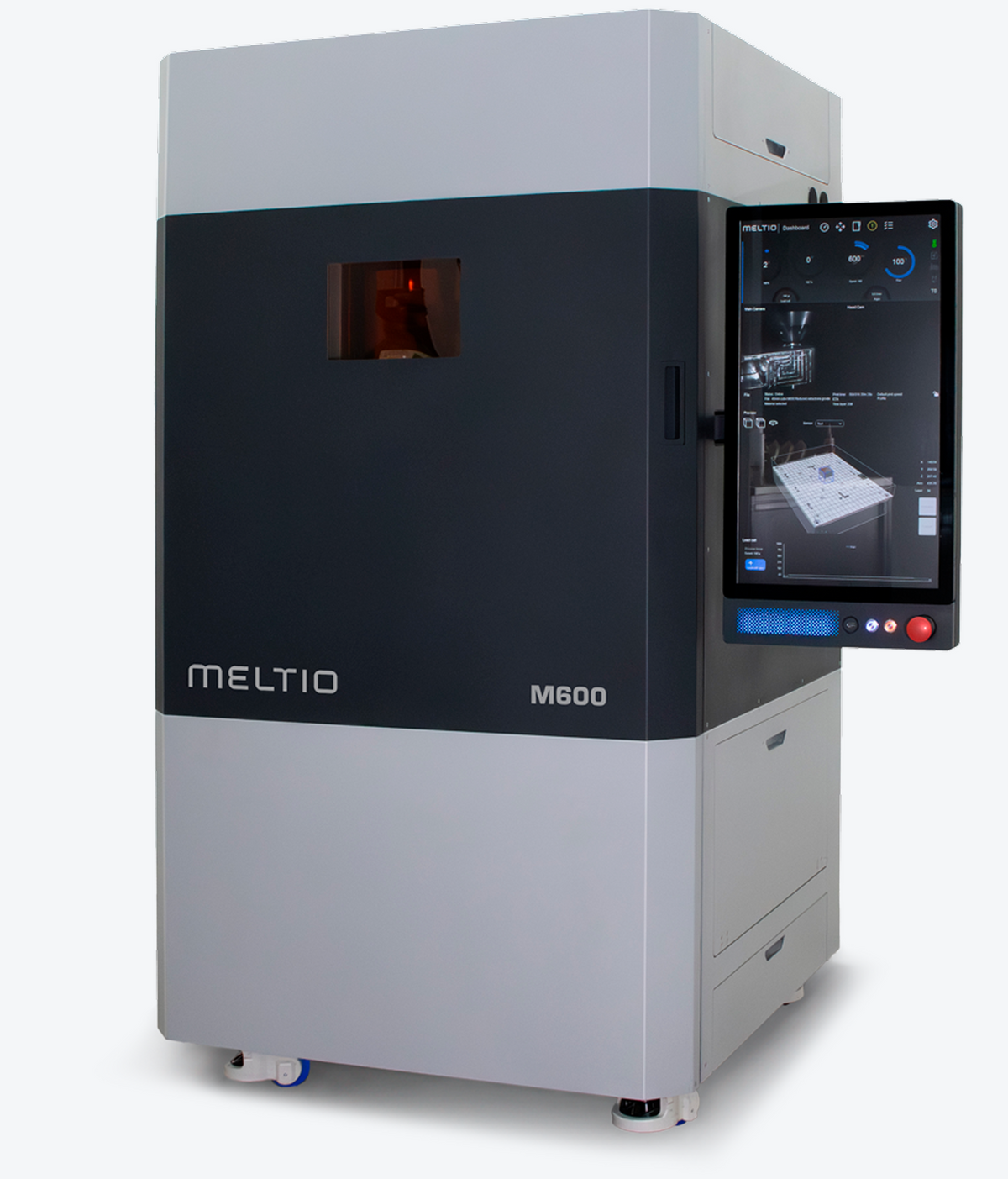

Meltio M600

The Industrial Wire-Laser Metal 3D Printer

- Blue Laser Technology

- 24/7 Production Cycle

- Inert Chamber Control

Why the M600?

Traditional machining wastes material and time. The M600 builds near-net-shape parts with wire feedstock that's safer and 10x more cost-effective than powder.

Traditional Machining

- 90% material waste through subtractive processes

- Long lead times for complex geometries

- High tooling costs for custom parts

- Limited design freedom due to tool access

Meltio M600 Solution

- Near-net-shape building minimizes post-processing

- Wire feedstock is safer and cheaper than powder

- Direct production from CAD in days, not weeks

- Complex internal features without assembly

Core Technologies

Engineering innovations that set the M600 apart

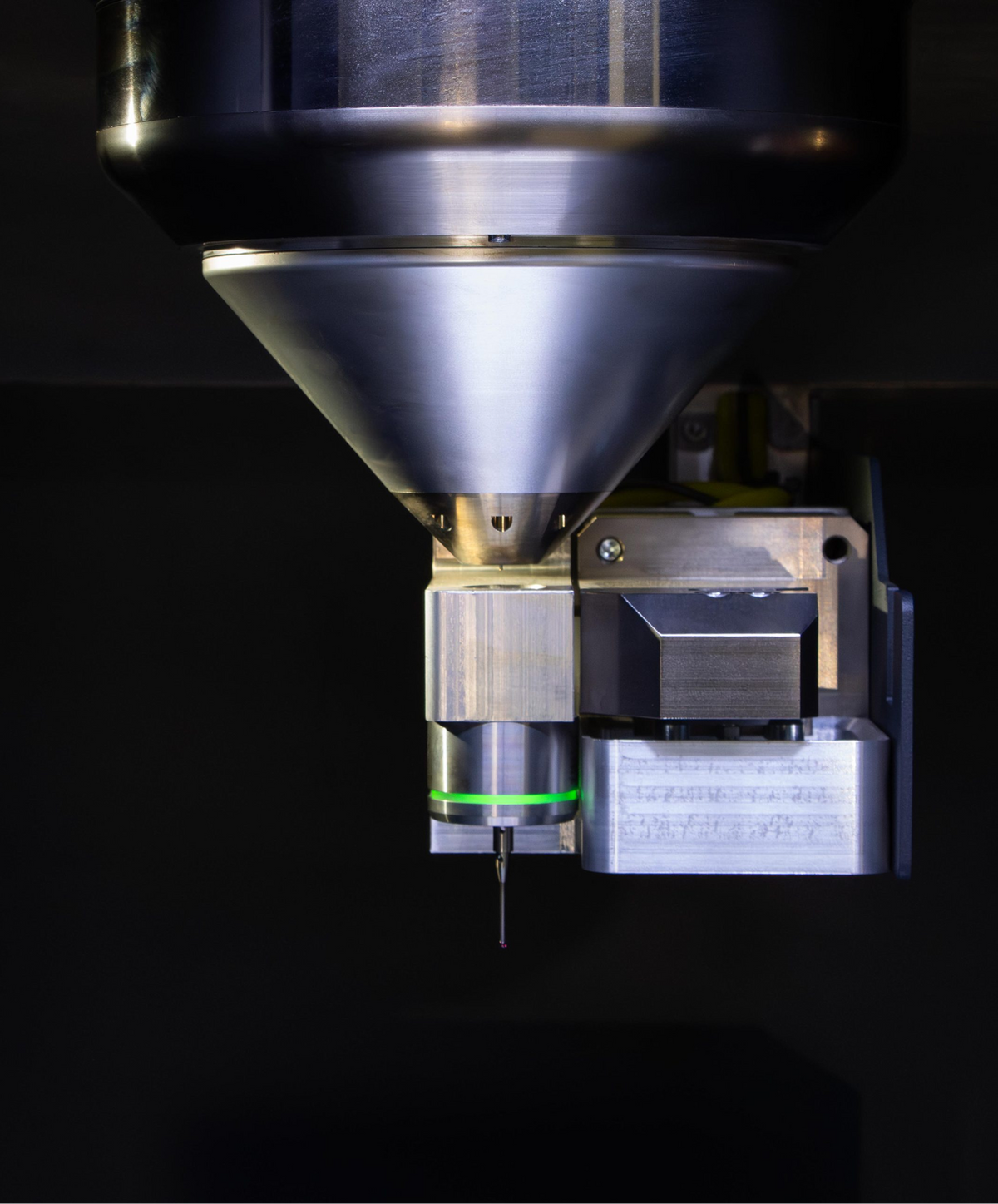

Blue Laser Technology (450nm)

Unlike traditional infrared lasers, blue lasers have superior absorption rates on reflective materials like copper and aluminum. This means faster processing speeds and better energy efficiency.

- 1000W laser power for precision control

- Optimized for reflective metal alloys

- Reduced heat-affected zones

Wire Feedstock System

Wire-based printing eliminates the safety and handling concerns of powder systems. No explosion risks, no powder management infrastructure, and 10x lower material costs.

- Dual-wire capability for multi-material parts

- Safe storage and handling

- Standard welding wire compatibility

Industrial Build Volume

With a build envelope of 300 × 400 × 600 mm, the M600 handles real production parts, not just prototypes. Perfect for aerospace brackets, tooling inserts, and custom fixtures.

- Z-axis height: 600mm for tall components

- Precision: ±0.1mm repeatability

- Heated build plate up to 200°C

Controlled Inert Atmosphere

The sealed chamber maintains <20 ppm oxygen levels during printing, ensuring consistent material properties and preventing oxidation in reactive metals like titanium.

- Argon atmosphere control system

- Critical for titanium and aluminum

- Ensures aerospace-grade quality

Compatible Materials

Industrial-grade metal alloys for demanding applications

Stainless Steels

- 316L (Marine/Medical)

- 17-4 PH (Aerospace)

- 304L (General Industrial)

- 15-5 PH (High Strength)

Titanium Alloys

- Ti-6Al-4V Grade 5

- CP Titanium Grade 2

- Ti-6Al-4V ELI (Medical)

- Custom Titanium Blends

Nickel Superalloys

- Inconel 625

- Inconel 718

- Hastelloy X

- Custom Ni Alloys

Technical Specifications

Complete engineering data for the Meltio M600

| Specification | Value |

|---|---|

| Build Volume (X × Y × Z) | 300 × 400 × 600 mm |

| Laser Type | Blue Laser (450nm wavelength) |

| Laser Power | 1000W continuous |

| Wire Feed System | Dual-wire capability |

| Wire Diameter | 0.8 - 1.2 mm |

| Chamber Atmosphere | Inert (Argon), <20 ppm O₂ |

| Machine Dimensions (L × W × H) | 1800 × 1200 × 2200 mm |

| Machine Weight | 1200 kg |

| Power Input | 380-400V, 3-phase, 32A |

| Power Consumption | 8-12 kW (printing mode) |

| Argon Supply | 99.999% purity, 10-15 L/min |

| Build Plate Material | Steel, heated up to 200°C |

| Layer Height | 0.5 - 2.0 mm (typical) |

| Positioning Accuracy | ±0.1 mm |

| Control Interface | 15.6" Industrial Touchscreen |

| Network Connectivity | Ethernet, USB |

| Safety Certifications | CE Marked, ISO 9001 |

Powered by Meltio Horizon

Dedicated toolpath generator optimized for 3-axis wire-laser printing. Slice complex geometries in minutes, not hours, with intelligent support generation and process parameter control.

Intelligent Slicing

Automated toolpath generation with optimization for wire-laser processes

Parameter Control

Full control over laser power, wire feed, and deposition strategy

Simulation & Preview

Visual simulation of build process before printing starts

Downloads & Resources

Technical documentation and case studies

Ready to See the M600 in Action?

Book a live demonstration at our Bergeijk facility or arrange a virtual consultation with our engineering team.