Wire-Laser Metal 3D Printing

The safest, most affordable path to industrial metal parts

Wire-laser technology eliminates the safety hazards and high costs of powder-based systems. Using standard welding wire and blue laser precision, we deliver industrial-grade metal 3D printing without the complexity.

Blue Laser Precision

450nm wavelength for optimal metal absorption

Why Wire Over Powder?

Traditional powder-based metal 3D printing requires hazmat infrastructure and extreme safety protocols. Wire-laser technology delivers the same results with 90% less complexity.

Powder Systems

Nieche hoge precisie

Metal powders are highly flammable. Requires inert atmosphere handling and explosion-proof facilities.

Hoge technologie en operatie kosten

Specialized metal powders cost 10x more than wire. €150-400/kg for powder vs €15-40/kg for wire.

Hoge materiaalkosten

Requires PPE, ventilation systems, and specialized waste disposal. Not suitable for standard factory floors.

Hoge veiligheids eisen

Unpacking parts from powder bed is messy, time-consuming, and requires powder recycling infrastructure.

Meltio Wire-Laser

Ideaal voor kleine tot grote producten

Wire feedstock is stable and non-explosive. No special storage or hazmat requirements. Safe for any factory environment.

Lage materiaalkosten en veilige handeling

Uses standard welding wire available from any supplier. Typical cost: €15-40/kg. Same materials, fraction of the price.

meerdere materiale in een proces beschikbaar

No powder mess. No ventilation requirements. Parts are ready immediately after printing without unpacking process.

Perfect voor near net shape producten

Integrates into existing manufacturing environments. No special facilities required. Argon gas is the only consumable.

10X

Lower Material Cost

Wire vs. Powder

ZERO

Explosion Risk

Safe Solid Feedstock

90%

Less Infrastructure

No Hazmat Facilities Needed

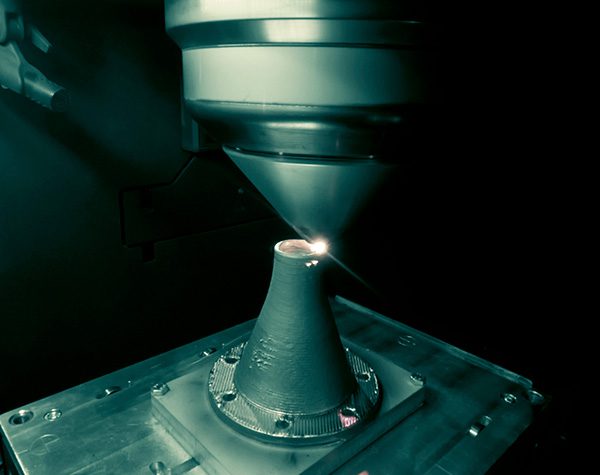

How Wire-Laser Printing Works

Three synchronized systems work together to build metal parts layer by layer with precision and control

Wire Feed

Standard welding wire (0.8-1.2mm diameter) feeds continuously from spools. No special handling required.

Materials:

- Stainless Steel (316L, 17-4PH)

- Titanium (Ti-6Al-4V)

- Inconel (625, 718)

- Aluminum Alloys

Laser Melting

Blue lasers (450nm) or IR lasers melt the wire tip into a controlled melt pool. Precise energy control ensures quality.

Technology:

- 1000W Laser Power

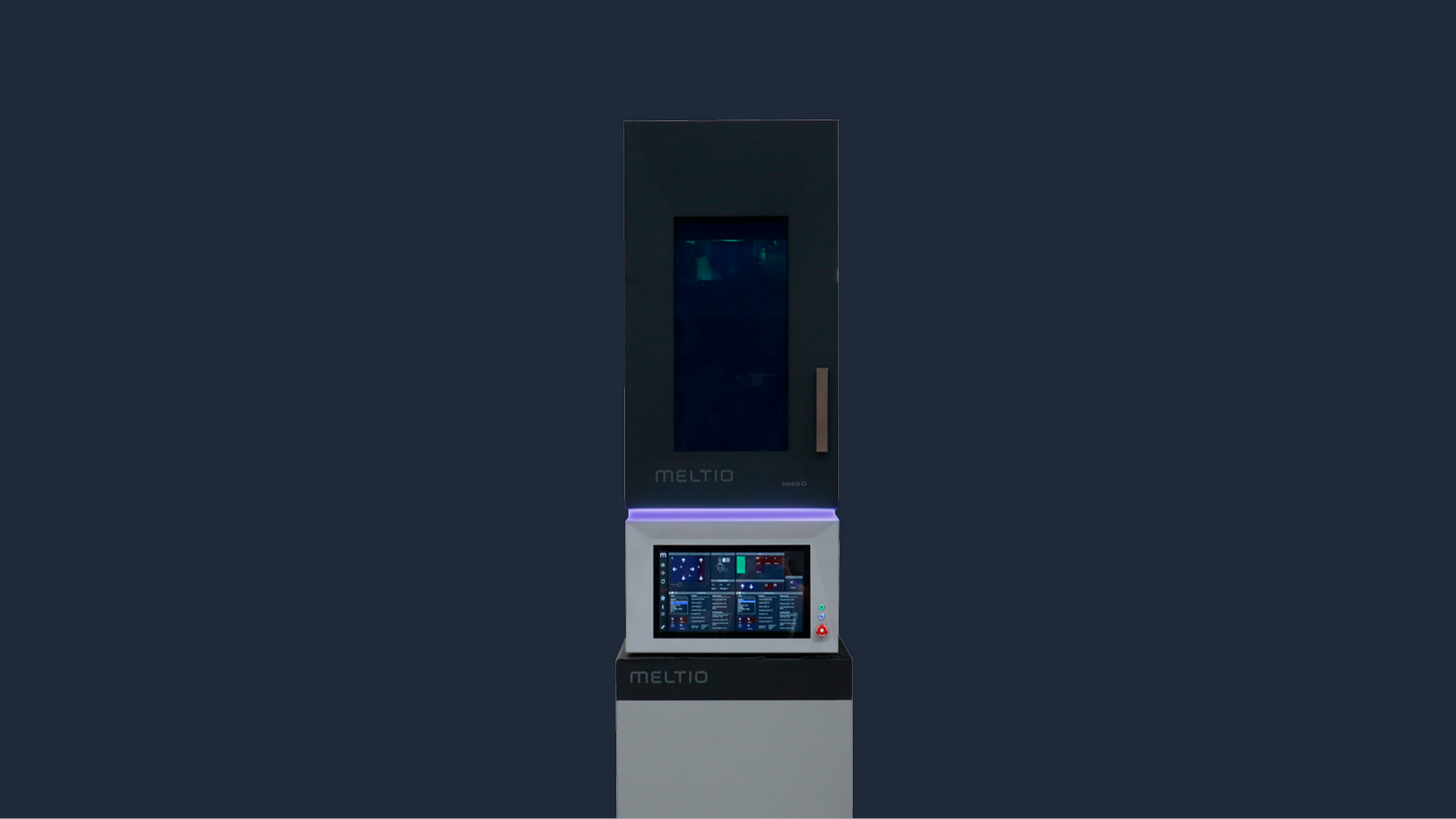

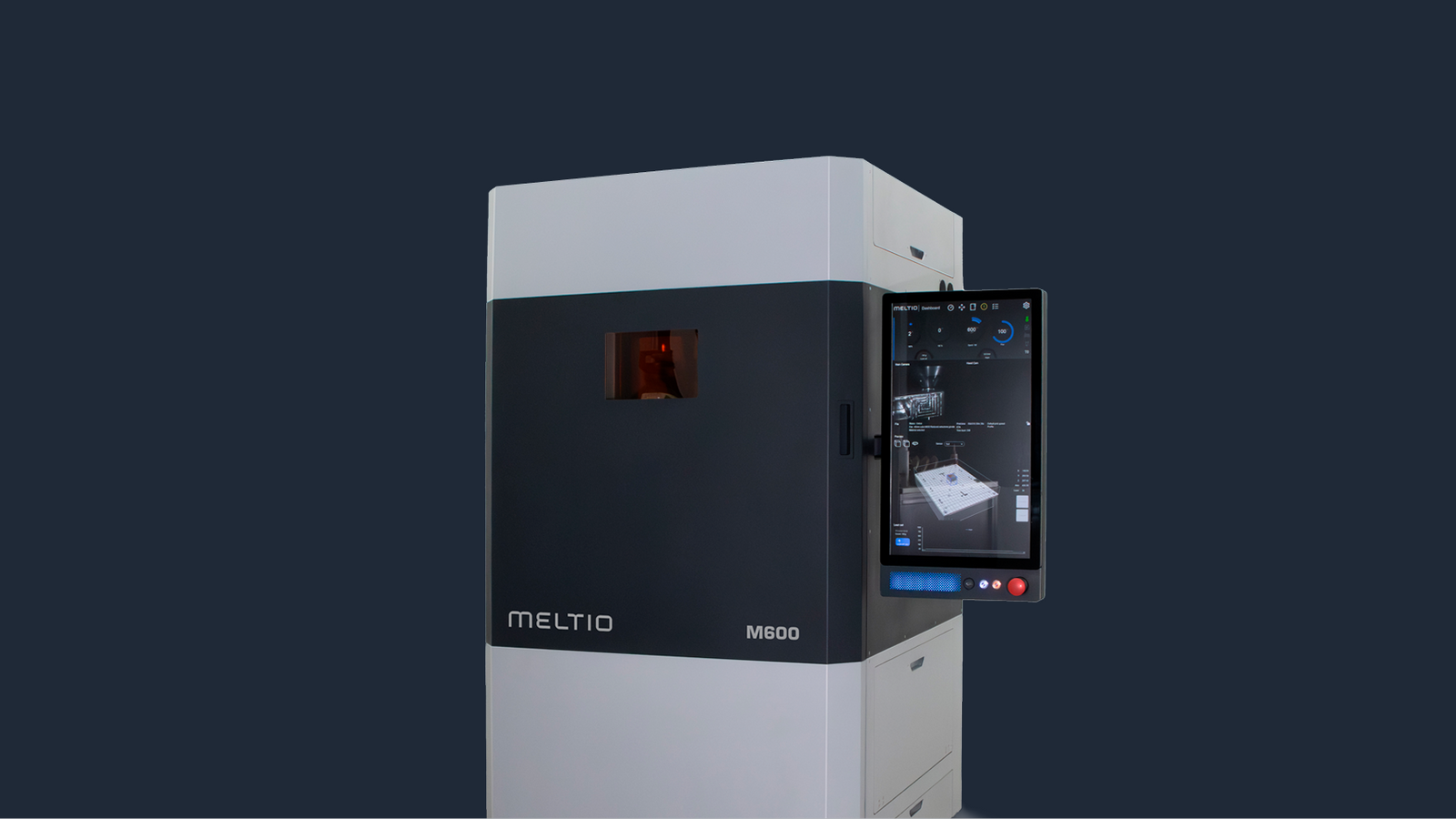

- Blue Laser (M600/M450)

- Optimal for reflective metals

- Real-time monitoring

Solidification

Material solidifies immediately, building near-net-shape parts layer by layer in an inert argon atmosphere.

Quality Control:

- Inert chamber (<20 ppm O₂)

- Layer-by-layer precision

- Dense, void-free parts

- Aerospace-grade quality

Synchronized System Architecture

All components work in perfect harmony for consistent results

CAD Model

Meltio Horizon

3-Axis Printing

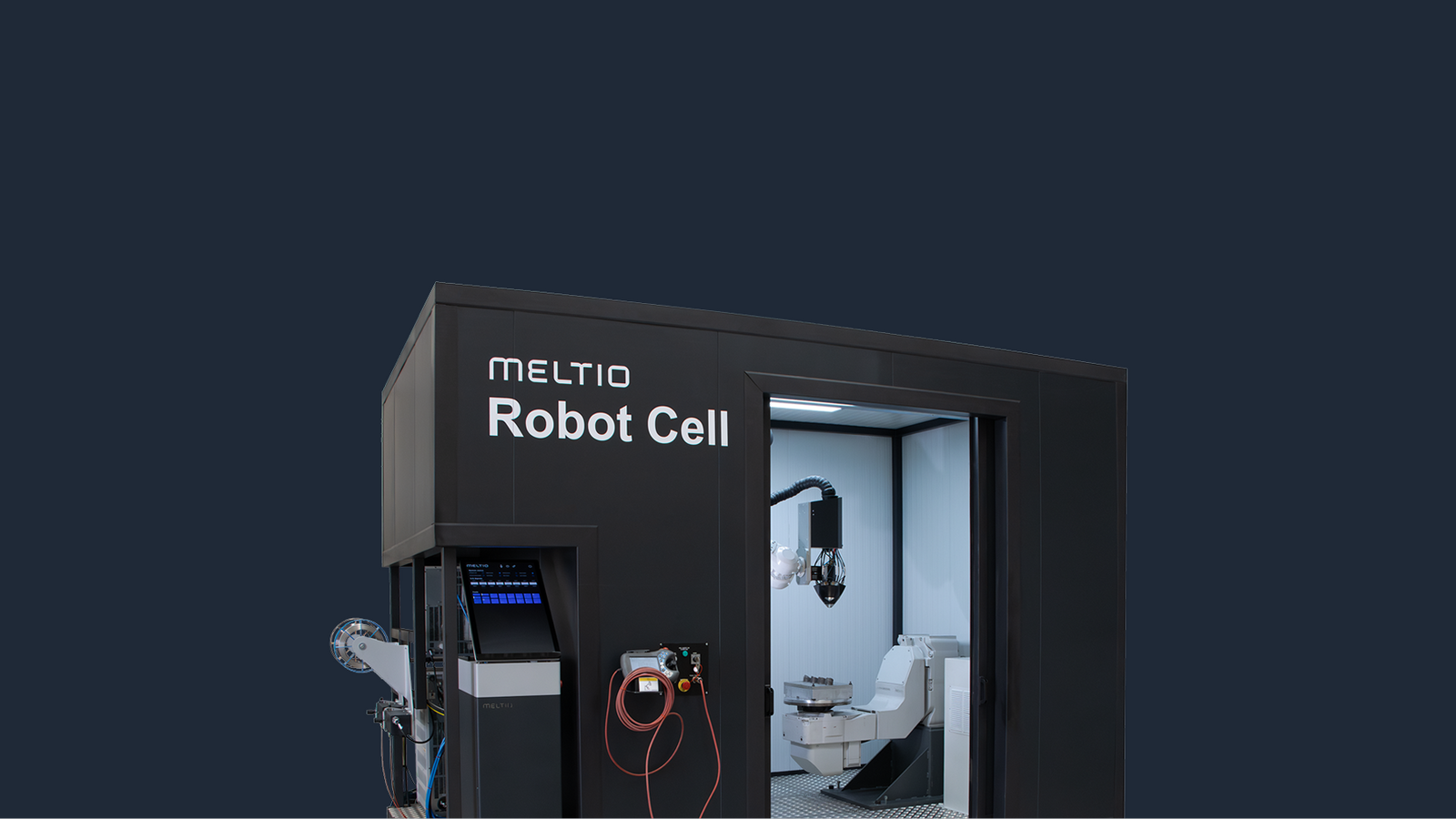

Choose Your Configuration

Four implementation paths to match your production requirements and facility constraints

Not Sure Which Configuration is Right?

Book a free 30-minute consultation. We'll help you choose the optimal setup for your application.

Schedule ConsultationCompatible Materials

Standard welding wire from any certified supplier

Stainless Steel

316L, 17-4PH, 304L

Mild Steel

ER70S-6

Titanium

Ti-6Al-4V, Grade 2

Inconel

625, 718

Nickel Alloys

Custom blends

THE BRAIN BEHIND THEHARDWARE

Meltio Horizon and Meltio Space provide the complete software stack for slicing, toolpath generation, and machine control.

MELTIO HORIZON

CAM software for 3-axis printing. Import STL, generate toolpaths, optimize parameters.

MELTIO SPACE

Multi-axis programming for robot and CNC integration. Advanced path planning.

REMOTE MONITORING

Track machine status, receive alerts, and access build history from anywhere.